Thermal Energy Storage (TES) tanks offer an innovative way to manage cooling costs and improve system performance. These tanks store chilled water during off-peak hours—when electricity rates are lower and cooling demand is minimal—and then discharge it during the day when demand and rates spike.

Here’s why more facilities are turning to TES systems:

Lower Energy Costs

By shifting cooling production to off-peak hours, facilities can dramatically reduce their electricity bills.

Load Shifting

TES tanks ease the burden on the electrical grid by reducing peak demand, which can also help avoid costly demand charges.

Improved Chiller Efficiency

Chillers often operate more efficiently at night thanks to cooler outdoor temperatures, further cutting energy use.

System Optimization

TES allows for smaller chillers to handle large cooling needs by spreading the load over time—potentially reducing upfront capital costs.

Greater Reliability and Flexibility

Stored chilled water provides backup cooling capacity during equipment issues or extreme conditions.

Environmental Benefits

By reducing peak power consumption—often supplied by less efficient, high-emission power plants—TES helps lower a facility’s carbon footprint.

Smarter Monitoring with Modbus Technology

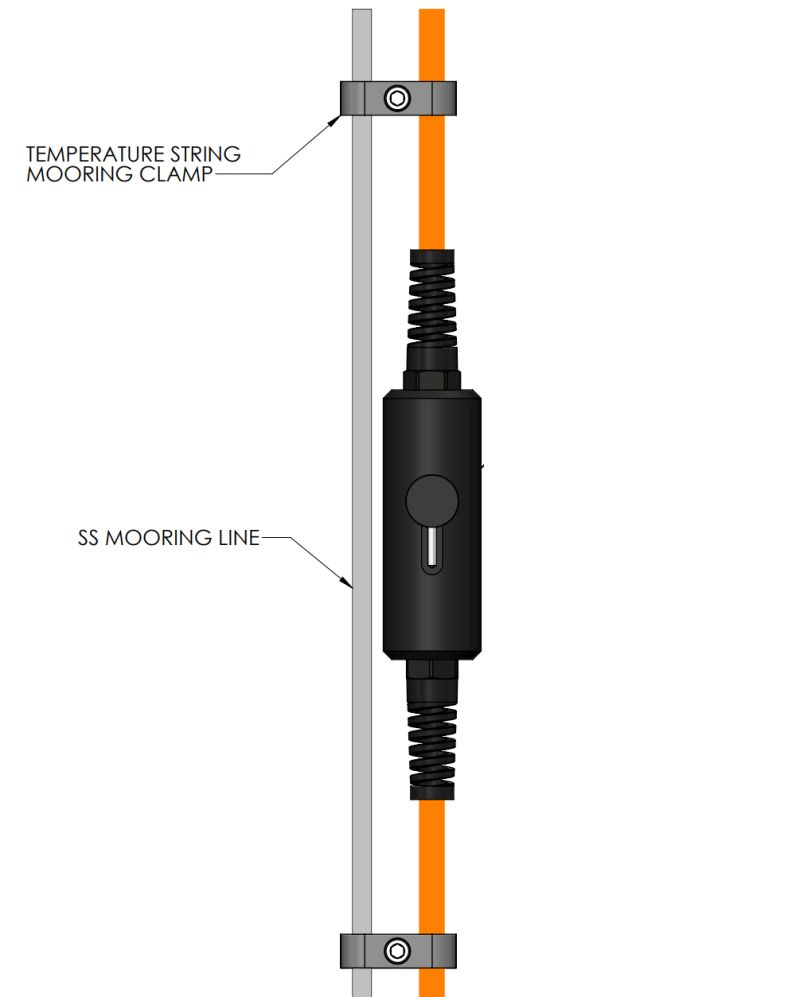

Inside a TES tank, water naturally stratifies: cold water settles at the bottom while warmer water rises to the top. Monitoring this temperature gradient is critical to system performance.

Traditionally, this meant using dozens of individual RTD sensors and transmitters—adding complexity, cost, and time to installation.

But there’s a better way.

Using Modbus RTU serial communication, we can install a multi-point thermocline sensor that reports all temperature points through just four wires—saving thousands on wiring, hardware, and BAS integration.

In the photo below, you’ll see the installation team raising the thermocline sensor up the side of the tank and into the stilling well. A custom flange supports the sensor’s mooring line. The entire system—assembled, installed, and wired—was up and running before lunch.